Process of Moxa

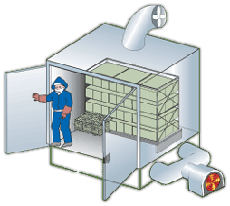

- ① Dehydration of mugwort leaves.

- In order to manufacture moxa from mugwort, the mugwort must be harvested between May and July, before it has grown too big, and then sun dried on a sunny day. After that, it should be stored in a dark room until winter. For the best quality, further manufacturing should take place in mid-winter, when it is extremely cold. The mugwort should once again be dehydrated, this time using a charcoal fire or briquette. About 187 kg of raw mugwort per day should be placed in the furnace room for a 24 hour period.

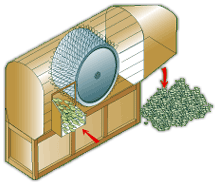

- ② Crushing the leaves.

- Once thoroughly dried, in order to make the mugwort leaves easy to put in the stone mortar, the mugwort leaves are cut to a uniform length using a cutting machine.

- ③ Rough grinding

- The revolution of the pestle of the stone mortar (a rough grinding stone) pushes the cut mugwort leaves into the mortar and crushes the leaves. After that, a sieve is used to sift through it and low-grade moxa is created.

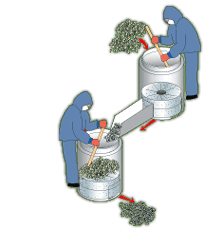

- ④ Fine grinding

- When making high-grade moxa, the moxa is finely ground for a second or third time (using different mortar and pestle sizes and revolution numbers). The revolution numbers and mortar and pestle sizes used are based on long years of experience.

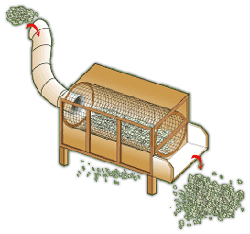

- ⑤ Sieving

- The moxa is separated from foreign substances using a rotating sieve. The finer the sifting, the higher the quality of the moxa.

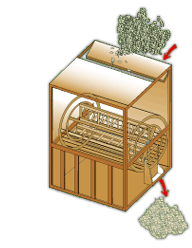

- ⑥ Winnowing

A number 1 and number 2 winnower (with differences in revolution number and size) are used to thoroughly remove any further impurities and create high-grade moxa. Quality is altered by revolution speed and time. It is said that raw mugwort produces only 2-3% the quantity of high-grade moxa.

*To provide stable quality moxa to customers, we store the moxa manufactured in Niigata's moxa factories, in Shiga's storehouses. Then every fiscal year, we blend the moxa, which is slightly different in quality each year because they are products of nature, and winnow for the final adjustment.

Ingredient of Moxa

-

In order to produce good moxa, the quality and quantity of the soft fuzz (composed trichome and glandular hair) which grows on the underside of Japanese mugwort is of particular importance.

Within this fuzz, particularly within the glandular hairs, is a volatile oil (eucalyptol = insecticide, tannic acid = antipyretic, terpene = scent) which is the active ingredient. It is said that domestic Japanese mugwort contains twice as much of this oil as other types of mugwort.

The higher the ratio of these glandular hairs, the better the fire that is produced. (This means that the moxa catches fire easily and burns out in a flash.) This creates a first-rate moxa in which no heat is felt.

-

On the other hand, trichomes create a soft and sticky moxa with good spread and high efficiency.

There are a variety of other requirements for the quality of raw mugwort which can create large differences in the moxa it produces. Good moxa produces only a small amount of ash (high-grade domestic moxa produces 3-4%) and contains a moderate amount of moisture (high-grade domestic moxa contains 11%). Other factors are the medical properties of the moxa, such as its effectiveness in sterilizing skin and the disinfection which is provided when smoke from the burning moxa drives away noxious gases, and its tranquilizing efficiency.

Because high-grade domestic moxa is made using the best manufacturing techniques and climate, it is easy to light and permeable with no feeling of heat. On top of that, it also has a wonderful fragrance, produces elegant smoke, and provides refreshment and equilibrium to both body and soul.

We believe that direct moxa made from this high-grade moxa allows for the best moxa experience.